Equipment start-up following an extended shut down period

Guidance for machinery, electrical installations and mechanical systems

properties.trackTitle

properties.trackSubtitle

A car left unused for an extended period of time may experience operational problems because the battery has gone flat, the handbrake could be seized in place and the footbrake may not operate as expected

Machinery, electrical installations and mechanical systems in commercial properties are no different

Here, we provide some basic guidance and specific system considerations for machinery, electrical installations and mechanical systems in commercial properties following extended shut down periods.

Our guidance for commercial property owners/building managers should not replace the defined maintenance start up processes and prescribed procedures of equipment/installation operation manuals or codes of practice.

A risk assessment should be carried out and documented before start up commences, and only qualified and authorised persons should be engaged in starting up machinery or electrical installations.

Basic start-up guidance

Machinery

- Refer to the user manual for specific start up procedures.

- Ensure all critical spare parts and tools are present.

- Safely isolate the machine and lock off supplies to make it safe.

- Clean all accessible parts of the machine.

- Examine the machine for leaks and check that lubrication levels are sufficient.

- Check plugged-in electrical parts are securely connected and there is no loose or damaged wiring.

- With the power still isolated, check control panel switches and buttons are working properly.

- Ensure that the machine settings and parameters are correct or in ‘neutral’ so that no part of the machine can move unless the operator triggers it to move.

- Where possible, move rotating, pivoting and sliding parts manually and lubricate where required in line with the machine’s maintenance manual.

- Replace all guarding after the necessary checks have been completed and safely start the machine slowly in parts. If possible, verify each part is operating in turn before engaging the next part.

- Where applicable, check that battery back-up is still working and all necessary PLC-type programs have been retained.

- After start-up, listen for any abnormal noises, and feel for any excessive vibration.

- Recheck the machine for leaks.

- The initial release of moving parts or dust on electrical parts may cause a burning smell. Isolate the machine if any such smell persists.

- Safely isolate the machine if you not going to continue using it.

Passenger lifts

- Check all landing doors are secure and aligned.

- Make sure the lift can be called at each landing.

- Ensure the lift is level with each landing.

- Ensure the car doors close properly.

- Test the alarm and intercom.

- When the lift is in operation, ensure there is no excessive vibration or noise.

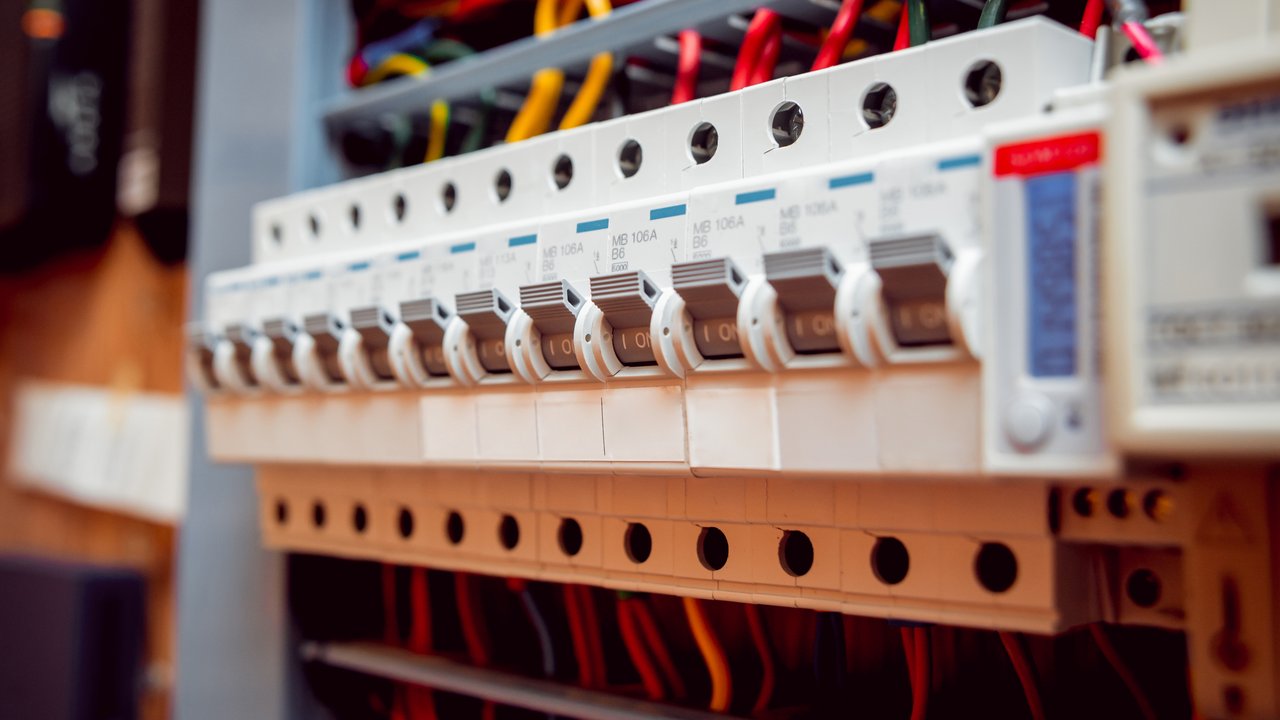

Electrical installations

Switching high-power electrical devices (such as lifts, machinery, air conditioners and refrigerators) creates sudden, brief demands for power which can upset the steady voltage flow in electrical systems. These are known as ‘switching surges’, and can be severe enough to damage components; immediately or gradually. Some equipment may fail to start after a long period of rest but a surge could cause a lot of damage to electrical installations and to supply authority equipment that you cannot access or repair.

Undervoltages, overvoltages and overcurrents caused by switching surges can also damage insulation or cause insulation flashover (an unintended electric discharge over or around the surface of an insulator). Damage and flashovers can often lead to power system outages, eroded components and increased risk of fire.

Overvoltage

Undervoltage

Overcurrent

Refer to operation and maintenance manuals for buildings relating to the correct isolation and start up procedures, and to individual manufacturers’ literature for single items of plant and equipment.

If areas of a commercial property have been electrically isolated, there is a sequence to follow to help avoid surges.

- Ventilate the building and turn the central heating on, if available, to reduce condensation within accessories and appliances.

- Work backwards through the distribution system before reinstating the power:

- Switch off and unplug equipment.

- Next, isolate the fixed final circuits (e.g. lights, machinery, equipment, etc).

- Next, safely isolate as many circuits as possible at each distribution board by switching off the miniature circuit breakers (MCBs).

To avoid power surges:

- Switch on the power at main isolator.

- Next, switch on the distribution board isolators.

- Next, switch on each MCB.

- Then, deisolate and plug in required equipment.

- Allow sufficient time for battery back-up systems to charge (e.g. emergency lighting).

Air conditioning systems

- Inspect the cooling unit for signs of damage, cracks or new signs of corrosion. If any irregularities are noted, an appointment with your appointed HVAC service company should be arranged.

- Remove any temporary covers and clean the condenser unit, removing any leaves or debris that may have accumulated.

- Verify refrigerant lines and gas pressure. Most modern systems have a low pressure indicator. If the pressure in the system has been depleted, seek advice from your HVAC service company.

- Inspect the air filter and clean or replace as necessary.

- Ensure grills are free from debris.

- Remove any stagnant water that may have accumulated after defrosting.

- Ensure all drains are clear from obstructions.

- Ventilate internal areas. Open windows and doors to allow fresh air to circulate prior to turning the system back on, and close before starting up the system (running the system with windows and doors open will put it under increased stress).

- Turn on the system, gradually bringing it online. Allow the system to run for 20 minutes at a low load until you can feel the air being cooled/heated.

- Slowly increase/decrease the setpoint by a couple of degrees every hour until the desired conditions are achieved.

- Verify the thermostat is set to the correct temperature. This will depend on seasonal conditions (cooling in summer, heating in winter).

- Check the condenser is running. During summer, the air coming out of the top should feel warm as the warm air is being removed from the building.

Local exhaust and ventilation (LEV) systems

When LEV systems have been out of use for some time, there is the possibility of the following occurrences; which may lead to damage and/or reduction in operational efficiency. Before the system is restarted, a visual check of the system should be undertaken; to include checks of the following:

- Fans and filters

- Water ingress

- Dampness in the system (which could lead to heavy residue ‘caking’ in the filters)Vermin ingress and nesting

Hot and cold water systems

Commonly found in hot and cold water systems, Legionella bacteria (the cause of Legionnaires’ disease; a type of pneumonia) can be contracted by the inhalation of water droplets. These water droplets are present at most system outlets such as shower heads, baths, taps, wet air conditioning systems, whirlpool baths and hydrotherapy pools.

Commercial property owners/building managers should carry out a full Legionella risk assessment of their hot and cold water systems following an extended shut down period, and ensure satisfactory measures are in place to control the risk.

The advice of a water treatment professional should be sought when reinstating these systems.

Pressure systems

Steam boilers/systems

If shut down for extended periods, steam boilers/systems can experience an introduction of condensate in the pipework. This can lead to potential water hammer hazards (caused by the introduction of steam into cold pipework that has not been sufficiently drained) which can cause injury to operating personnel and others working within the vicinity of the plant. Therefore, the following steps should be considered to minimise the hazard:

- Introduce steam into the cold pipework gradually to avoid the risk of thermal shock and to reduce the chance of water hammer.

- Ensure the pipework system is completely drained when cold, and pay attention to areas where condensate can collect; which might include sagging lengths of pipework, vertical legs, changes of slope, dead ends, etc.

- Steam traps to maintain them, in accordance with manufacturers’ instructions.

- Use isolating valves to permit the gradual warming of the system.

Compressed air systems

- Check compressor oil levels are correct.

- Ensure all compressors are well ventilated.

- Drain all dryers, traps, pipework and receivers of condensate.

- Ensure all filters are clean.

Hot water heaters

- Ensure air is completely vented from the system.

How HSB can help

HSB Inspection Services: Our network of competent, multi-skilled Engineer Surveyors help customers throughout the UK and Ireland to maintain workplace equipment safety, optimise the efficiency of plant and equipment, and comply with applicable health and safety legislation; covering boiler/pressure, lifting, electrical/mechanical, dust and fume extraction, power press equipment, and fixed wiring installations.

HSB Risk Management Solutions: We can help businesses to reduce risks, costs, and deliver compliance via improved analysis of their equipment and health and safety practices. Consisting of three services, each service is further split into modules, allowing customers to build them to fit their business.