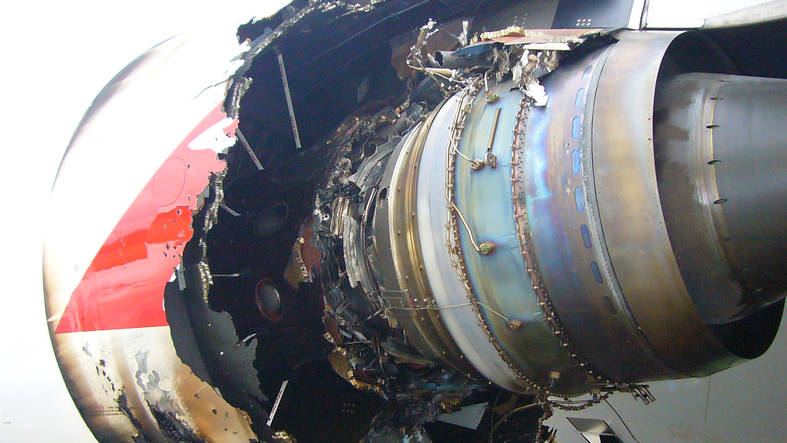

Oil leak believed to be the cause of the fire

New loss dimension

Fortunately, the crew and passengers were left unscathed by the flight and the emergency landing in Singapore following the engine’s dramatic explosion. After a few days, however, aviation insurers discovered that the loss sustained by the A380 had reached a whole new level in financial terms. In addition to the physical damage to the port wing of the Airbus with damaged fuel tanks, hydraulic lines, power supply lines and control lines, the hydraulic systems were also only partially intact and the buoyancy aids were likewise out of order. But the damage to individual components was just part of the story: the entire aircraft structure was affected as a result of the excess weight and uneven weight distribution during the emergency landing. This is due to the new lightweight composite technology used in construction of the A380. Qantas CEO Alan Joyce told the trade magazine Air Transport World that work on the wide-body jet would cost A$ 157m (€113m). Qantas and Rolls-Royce reached an out-of-court agreement in June 2011. According to Joyce, Qantas accepted the engine manufacturer’s offer of A$ 95m (€70m). Rolls-Royce anticipates losses of some £56m for 2010. All in all, this is the costliest hull repair loss in the history of passenger aviation. Despite the close collaboration between Airbus manufacturer EADS and Qantas, the repair work on the severely damaged A380 was a protracted process. The aircraft was not handed over to Sydney until 21 April 2012. On 28 April, the A380 was put back into service with a flight to Hong Kong.

You can find a detailed version of this article in the current issue of our Topics Schadenspiegel.

Munich Re Experts

Related Topics

properties.trackTitle

properties.trackSubtitle