Waste can be found wherever there are mining operations. Non-solid waste is collected in basins called tailings ponds, which are contained by dams. The failure of such a dam can have catastrophic consequences. If structures like these are to remain insurable, their individual risk situation must be analysed.

In contrast to water reservoirs, the retention structures for tailings disposals are either made from crushed rocks or, in the worst case, from dried waste residue. In order to seal the dams, they are given a core made from clay and in some cases plastic liners as well. Since the mine life of many operations is longer than originally planned because of increasing raw material prices, the dams may also need to be raised. Depending on the extraction method used, this can be done with either waste rock or dried tailings, which sometimes contain toxic chemicals from the treatment process.

Unlike reservoirs, which can be drained for maintenance, tailings dams must remain reliable over their entire operational life. In principle, they are built to last for ever, and ideally will be revegetated after a mine has closed down. While the mine is in operation, they must be stable enough to withstand the pressure from the tailings they hold. Unfortunately, this is not always the case. Canada‘s Mount Polley dam burst in 2013 and in 2015 the Samarco dam in Brazil failed.

The most frequent causes for incidents in tailings storage facilities (TSF) are earthquakes, overflow and landslides. In the case of quakes, either the dam itself can become unstable, or it can fail as a result of what is known as liquefaction. The maximum volume of a TSF can be exceeded by high precipitation, with the result that tailings escape from the basin. The dam itself is often damaged in the process. If the slopes of tailings dams are not flat enough, or not sufficiently compacted during construction, landslides occur that significantly compromise the stability of the dams.

The more expensive alternative technique is “dry stacking”, in which the processing residue is completely dried before being deposited. The material is piled up and compacted. This removes the need to construct large dams.

New standards for tailings basins

The highest dams today are up to 240 metres tall, and will grow even higher in the future. By way of comparison, the Hoover dam in the south-west of the USA measures 221 metres in height. TSFs are therefore among the largest man-made structures in the world. In the light of this trend and the aforementioned incidents, the mining industry has recognised the need for action. In December 2015, the International Council on Mining and Metals, a consortium of the world‘s 23 largest mining and metal companies, announced that it intended to review standards for the storage of tailings.

A rethink has also begun in the insurance industry after dam failures over the last few years triggered several major losses. The objective is to be able to estimate the risks more accurately, to ensure that tailings dams remain insurable in the future. It would be sensible in this context to separate the insurance of mining, and the special risks it involves, from standard property insurance. Munich Re has already adopted this approach in its Corporate Insurance Partner (CIP) unit. Unlike with the oil and gas sectors, there has traditionally been no separate line of business for mining in the insurance industry. Insurance policies are simply adapted from the policy forms for “standard” property risks in other industries by adding specific amendments for mining. As a result, product development has failed to keep pace with the industry’s needs and risks.

Lump-sum agreements and higher limits

The shortcomings become apparent in the area of business interruption. Loss of revenue due to business interruption is only covered if triggered by an insured property-damage loss. But tailings from mining operations are a product of no value, and thus cannot be covered under generic property insurance. This means that mining companies actually have no way to insure against business interruption if the dam on a sludge basin fails. On the other hand, it is impossible to operate a mine without a functioning TSF, since operations would have to close down if the processing residue cannot be disposed of.

Mining companies were assisted in their search for a solution to this dilemma by the soft market conditions of the last few years. This made it possible for them to conclude lump-sum agreements with insurers which also covered losses from business interruption without property damage triggers. The limits for these have steadily increased as market conditions have become softer.

Individual risk assessment necessary

What is needed, however, is a different approach: risks must be correctly assessed if they are to be insured commensurately. This requires experts in the field of mining who can work closely together with the respective clients. Munich Re has developed a questionnaire for this purpose, which forms the basis for the individual risk assessment. This should help calculate the critical risk scenarios, based on which the scope of cover and limits of indemnity can then be determined. The relevant factors include the age of the TSF, its probable service life, and the expected output of the operations. One exclusion criterion, for example, would be if the level of the sludge in the retention basin was just below the top of the dam. That would pose a substantial risk of the dam overflowing in the next heavy rain event.

If the questionnaire produces no exclusion criteria, the next step is for the underwriters to individually determine the stability of the tailings dams based on geotechnical reports. This is because each of these structures is different due to the varying geological conditions. Some of the important factors here are the material the dams are made from, the method in which they have been raised, and the properties of the soil on which they were built. In this evaluation process, Munich Re has the advantage that it has been supporting individual mining projects for decades and can draw on the expertise gained in this area.

Lump-sum covers for risks emanating from tailings dams harbour substantial risks for insurers because clients are requesting ever-larger sums insured. Insurers will have no option but to separate mining from general property insurance, and to find individual solutions in the same way as is customary in oil and gas business. In Corporate Insurance Partner, Munich Re has already adopted this approach with an experienced team of experts for various industries, and has also created a successful model for technical underwriting with its experienced mining team.

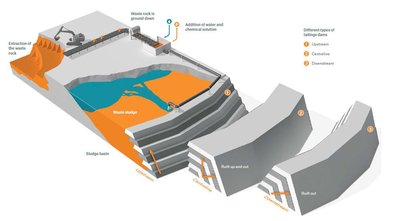

How sludge basins are formed

In order to get at valuable minerals, mining companies extract large quantities of rock. This first has to be ground down, and is then generally processed with the addition of chemical solutions. The lower the concentration of valuable materials, the higher the proportion of waste sludge that accrues. These tailings, as they are called, are sometimes contaminated with chemicals and are pumped into large sludge basins. The basins are generally contained by earthworks. Since the period during which a mine can be operated at a profit is usually extended by increases in raw material prices, the sludge basin frequently needs to be expanded. The companies manage this problem by successively raising the retaining dam.

Tailings dams are of varying stability, depending on their design. With the popular upstream design, the upper layer of wash residue is dried and used as the foundation for the next-higher earth barrage (see the diagram on the left). This variant has the advantage that the dam can be erected with little effort and therefore at a low cost. However, earthworks like these are the least stable, particularly if raised too quickly, i.e. before the top layer of waste has dried sufficiently. Much more solid structures are obtained if the original dam is raised centreline (2) or downstream (3).