Engineering inspection services

LOLER inspection: Lifting equipment

Regulations

properties.trackTitle

properties.trackSubtitle

What is a LOLER inspection?

The UK's Lifting Operations and Lifting Equipment Regulations (LOLER) and Provision and Use of Work Equipment Regulations (PUWER) place duties on people and companies who own, operate, or have control over lifting equipment.

Periodic engineering inspections of workplace plant, machinery and equipment form a vital part of an employer’s duty; ensuring the health, safety and welfare of their employees and workplace visitors. Inspections also ensure employer conformity to health and safety regulatory requirements and, ultimately, add value by helping the business to operate efficiently.

A requirement of LOLER and PUWER is that, in many cases, equipment used for lifting is subject to statutory, periodic 'thorough examinations' by a 'Competent Person'.

What is a 'Competent Person'?

The UK Health & Safety Executive defines a 'Competent Person' as "someone who has the necessary skills, experience and knowledge to manage health and safety".

Depending on the particular legislation, the Competent Person can be either an individual or the body which employs the individual to provide inspection services.

What types of lifting equipment are covered by LOLER?

Many types of businesses and organisations utilise various types of lifting equipment which can often be in regular use, with varying loadings and duty cycles.

Lifting equipment might include passenger/goods lifts, escalators, cranes, electric chain blocks, hoists, fork-lift trucks, and mobile elevating work platforms, whilst lifting tackle and accessories may include chains, slings, and eye bolts; to name a few.

| Equipment category | Legislation (1) |

|---|---|

| Lifting | Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) Provision and Use of Work Equipment 1998 (PUWER) |

| Boiler/pressure | Pressure System Safety Regulations 2000 (PSSR) |

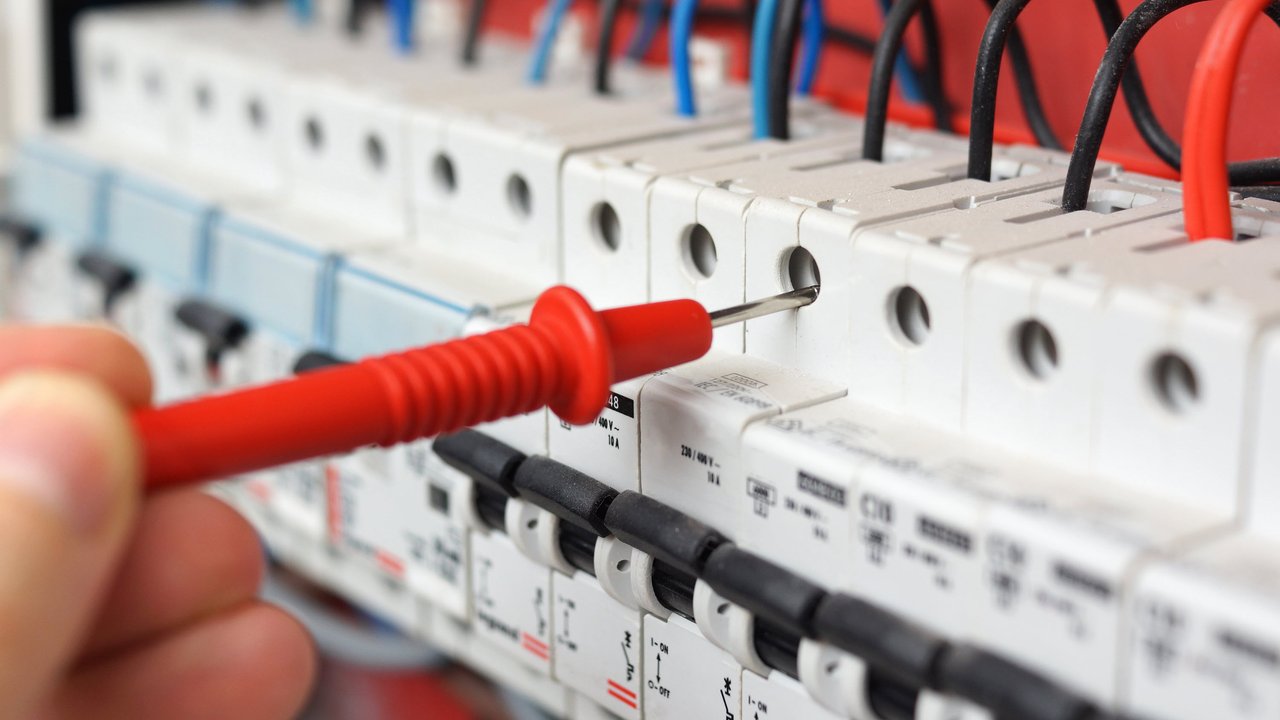

| Electrical/mechanical | Provision and Use of Work Equipment 1998 (PUWER) |

| Local exhaust ventilation | The Control of Substances Hazardous to Health Regulations 2002 (COSHH) |

| Power presses and associated machinery | Provision and Use of Work Equipment 1998 (PUWER) |

| Fixed electrical wiring | Electricity at Work Regulations 1989 (EAWR) |

About us

Multi-skilled

Engineer Surveyors

Our network of technically-experienced, competent engineers are located throughout the UK and Ireland.

UKAS

accredited

HSB Engineering Inspection Services Limited are a UKAS-accredited Inspection Body (No. 0010).

RoSPA President's

Award 2025

Awarded following eleven consecutive gold awards.

HSB

Connect

Provides customers with direct access to their key inspection reports and documentation via our online inspection reporting tool.

UK-based arm of

HSB Group

The equipment breakdown insurance and inspection market leader since 1866.

...very professional, giving us great confidence that our equipment has been competently inspected.