Disinfectant fogging and electrical risks

properties.trackTitle

properties.trackSubtitle

0:00

Disinfectant fogging is an established process used in industries such as pharmaceutical, healthcare, critical production, and laboratories, to efficiently eliminate germs on exposed surfaces and difficult-to-reach areas.

What is fogging?

What can go wrong?

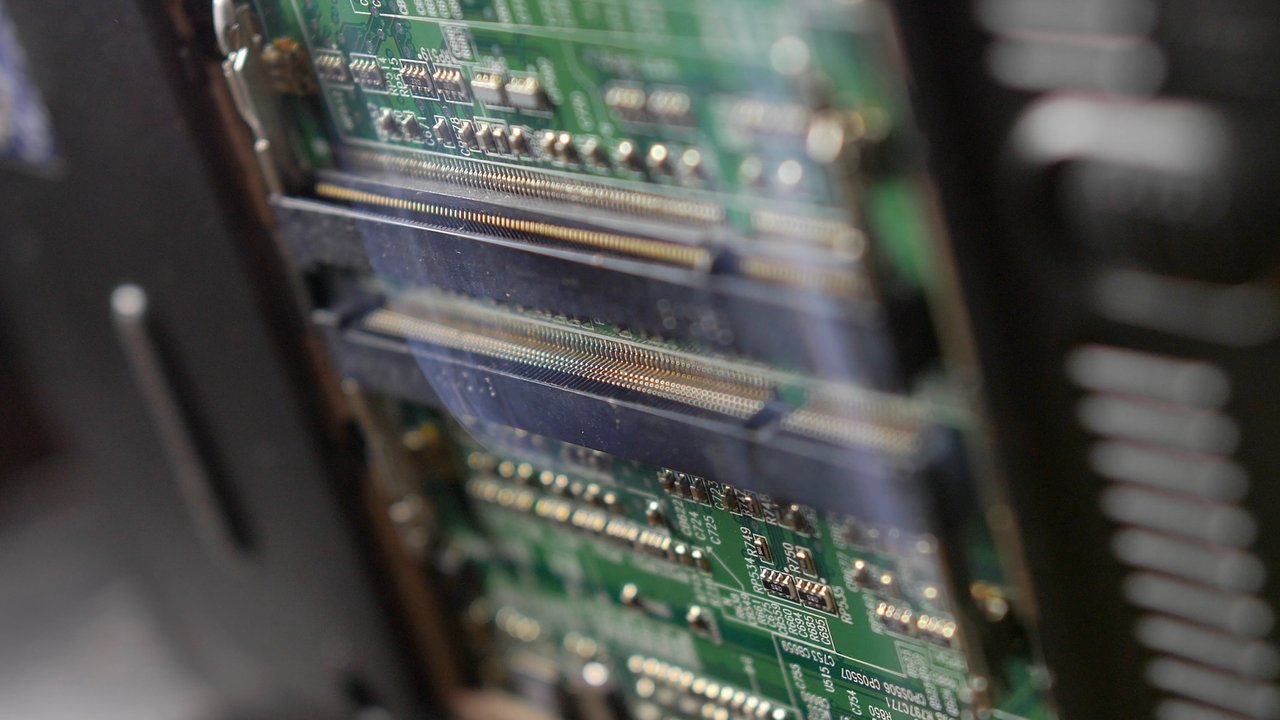

Excessive fogging, failure to follow established guidelines, and using the wrong disinfectants may lead to failures of vulnerable electrical and electronic components.

Early warning signs include:

❌ Visual evidence of corrosion

❌ Discoloration

❌ Contaminated surfaces

Factors affecting the severity of damage caused by fogging

Frequency and duration of applications

Method of dispersion

Type of disinfectant

- Are Material Safety Data Sheets available for the disinfectant?

- Is the disinfectant selected based on a total risk assessment of effectiveness and potential negative consequences?

Knowledge level and experience of fogging personnel

- Is the process carried out by an experienced vendor or untrained personnel?

- Is the technician trained in proper fogging methods and aware of the hazards of the applied disinfectants?

Environmental rating of the electronic enclosures

- Are the cabinets ventilated?

- Do they have a filtering system?

- Are the cabinets equipped with fans that draw air into the cabinet?

- What is the proximity of the air intake to the fogging nozzle?

The operational status of the equipment

- Is the electrical equipment energized and operating during fogging?

- Is the equipment properly shut down before fogging?

For more information on fogging and electrical components, NEMA’s complete COVID-19 Cleaning and Disinfecting Guidance for Electrical Equipment is available for download here.

The tips offered here are intended to complement and not replace the recommendation of the equipment manufacturer.