HSB Inspection Services

We listen. We act. We keep our customers safe.

Broker/Agent trading options:

properties.trackTitle

properties.trackSubtitle

Periodic engineering inspections of workplace plant, machinery and equipment form a vital part of an employer’s duty; ensuring the health, safety and welfare of their employees and workplace visitors.

Inspections also ensure employer conformity to health and safety regulatory requirements and, ultimately, add value by helping the business to operate efficiently.

Throughout the UK and Ireland, our network of competent, multi-skilled Engineer Surveyors are focused on helping businesses, of all sizes and industry types, to:

- maintain workplace equipment safety

- optimise the efficiency of plant and equipment

- comply with applicable health and safety legislation

We provide impartial engineering inspection services in the role of ‘Competent Person’ to assist with statutory inspections across a vast range of plant and equipment.

What is a 'Competent Person'?

UK

The UK Health & Safety Executive defines a 'Competent Person' as "someone who has the necessary skills, experience and knowledge to manage health and safety".

Depending on the particular legislation, the Competent Person can be either an individual or the body which employs the individual to provide inspection services.

Ireland

UK

| Equipment category | Legislation (1) |

|---|---|

| Boiler/pressure systems | Pressure System Safety Regulations 2000 (PSSR) |

| Lifting | Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) |

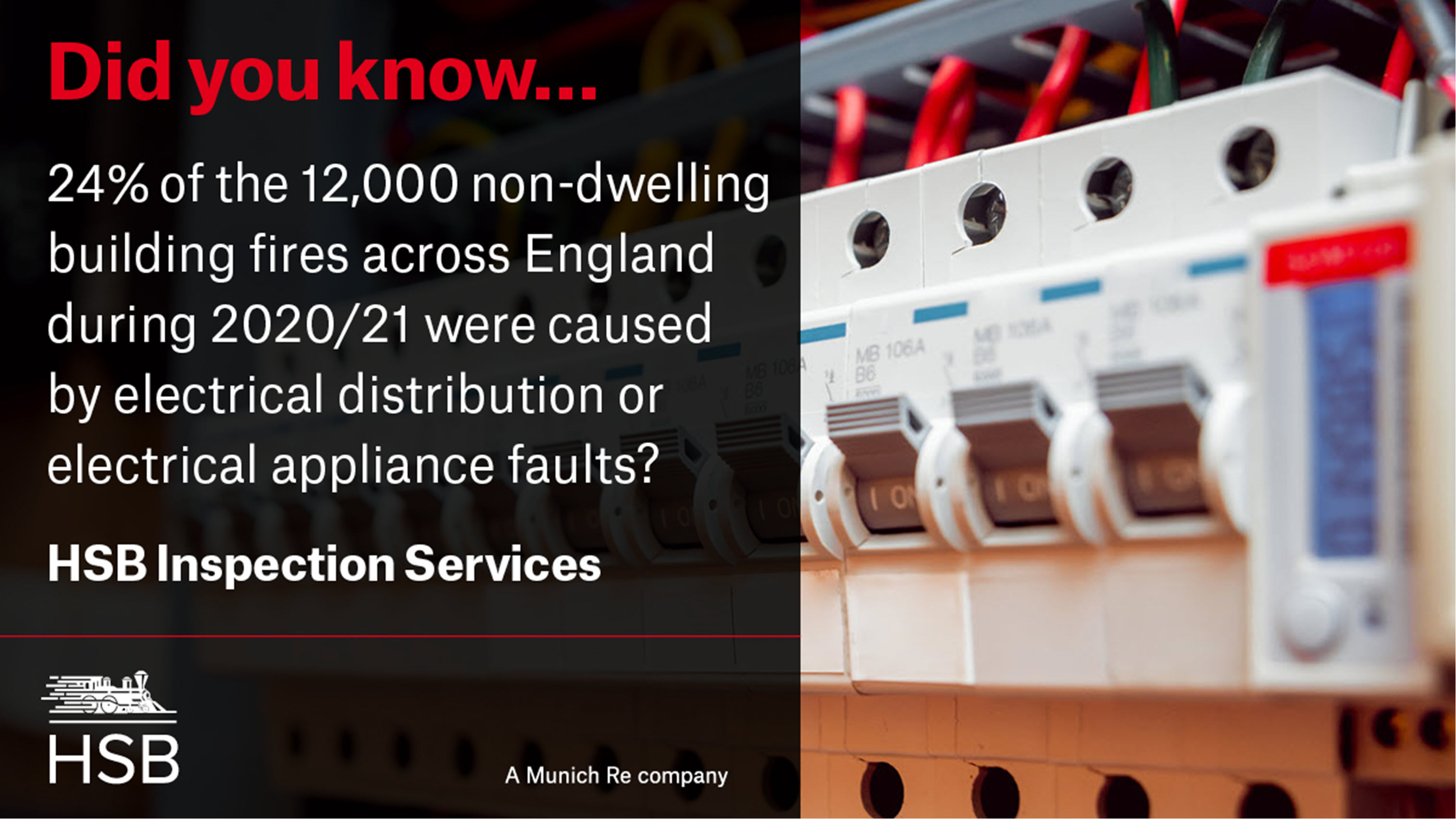

| Electrical/mechanical | Provision and Use of Work Equipment Regulations 1998 (PUWER) |

| Local exhaust ventilation | The Control of Substances Hazardous to Health Regulations 2002 (COSHH) |

| Power presses and associated machinery | Provision and Use of Work Equipment Regulations 1998 (PUWER) |

| Fixed wiring (electrical) | Electricity at Work Regulations 1989 (EAWR) |

Within the UK, we can also inspect many types of equipment used by the general public which do not necessarily require statutory examinations.

Ireland

| Equipment category | Legislation |

|---|---|

| Boiler/pressure systems | S.I. No. 445 of 2012: Safety, Health and Welfare at Work (General Application) (Amendment) Regulations 2012 |

| Lifting | S.I. No. 299 of 2007: Safety, Health and Welfare at Work (General Application) Regulations 2007 |

| Electrical/mechanical | S.I. No. 299 of 2007 (Regulation 30): Safety, Health and Welfare at Work (General Application) Regulations 2007 |

| Local exhaust ventilation | Health & Safety Authority: Local Exhaust Ventilation (LEV) Guidance document |

| Power presses and associated machinery | S.I. No. 299 of 2007: Safety, Health and Welfare at Work (General Application) Regulations 2007 |

| Fixed wiring (electrical) | S.I. No. 299 of 2007 (Part 3): Safety, Health and Welfare at Work (General Application) Regulations 2007 |

...very professional, giving us great confidence that our equipment has been competently inspected.

Brochures

Why choose HSB?

- A leading specialist provider of engineering inspections in the UK and Ireland

- Proactive service carried out by our network of competent, technically-experienced Engineer Surveyors located throughout the UK and Ireland

- Inspection services accredited by UKAS (United Kingdom Accreditation Service)

- Provides customers with direct access to their key inspection reports and documentation via our online inspection reporting tool, HSB Connect

- UK-based arm of HSB Group, the equipment breakdown insurance and inspection market leader since 1866

Contact us

Spotlight: HSB Risk Management Solutions

Equipment Condition and Performance Services | Vertical Transportation Services | Health and Safety Services

We can help businesses to reduce risks, costs, and deliver compliance via improved analysis of their equipment and health and safety practices. Each service is further split into modules, allowing customers to build them to fit their business.